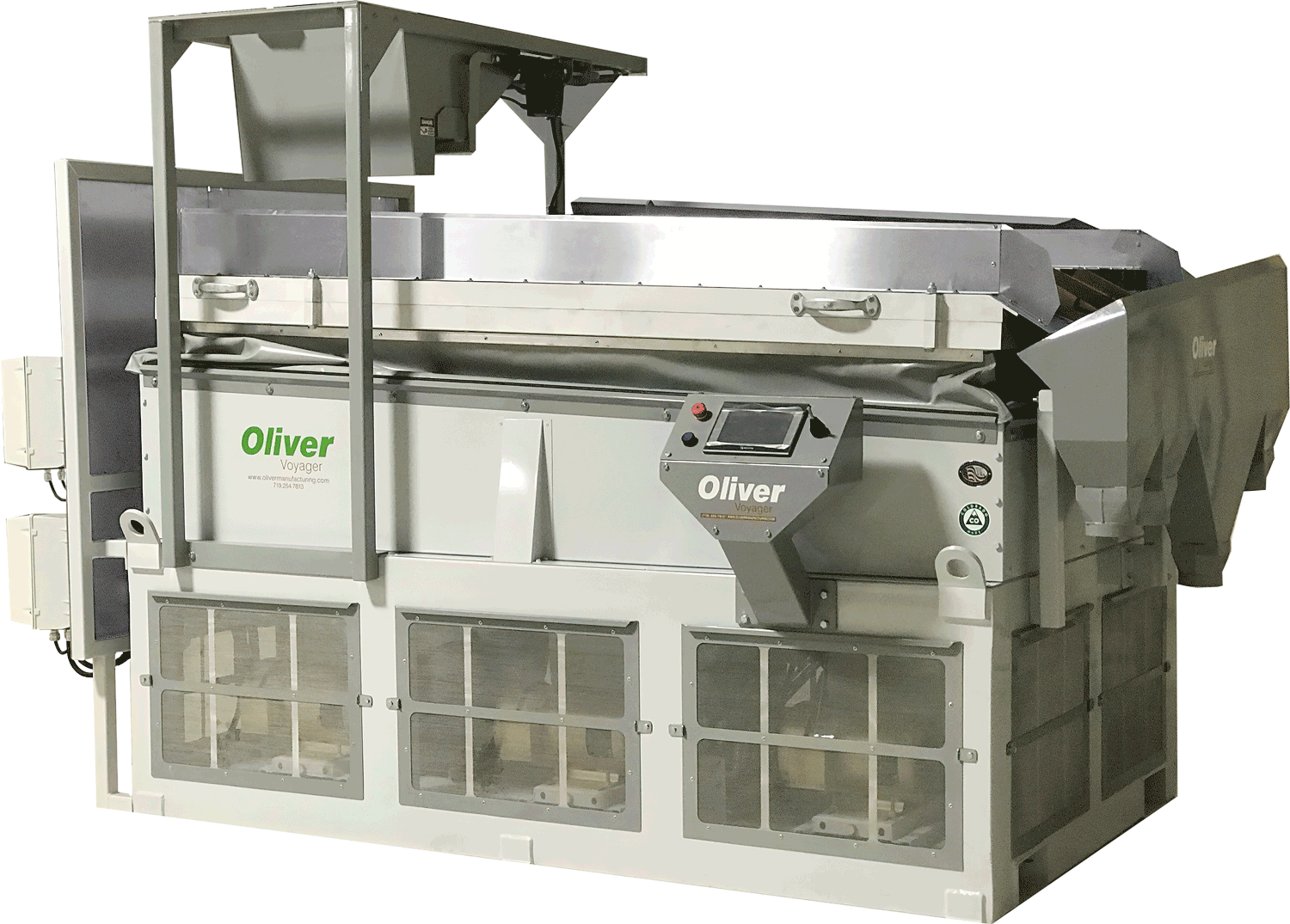

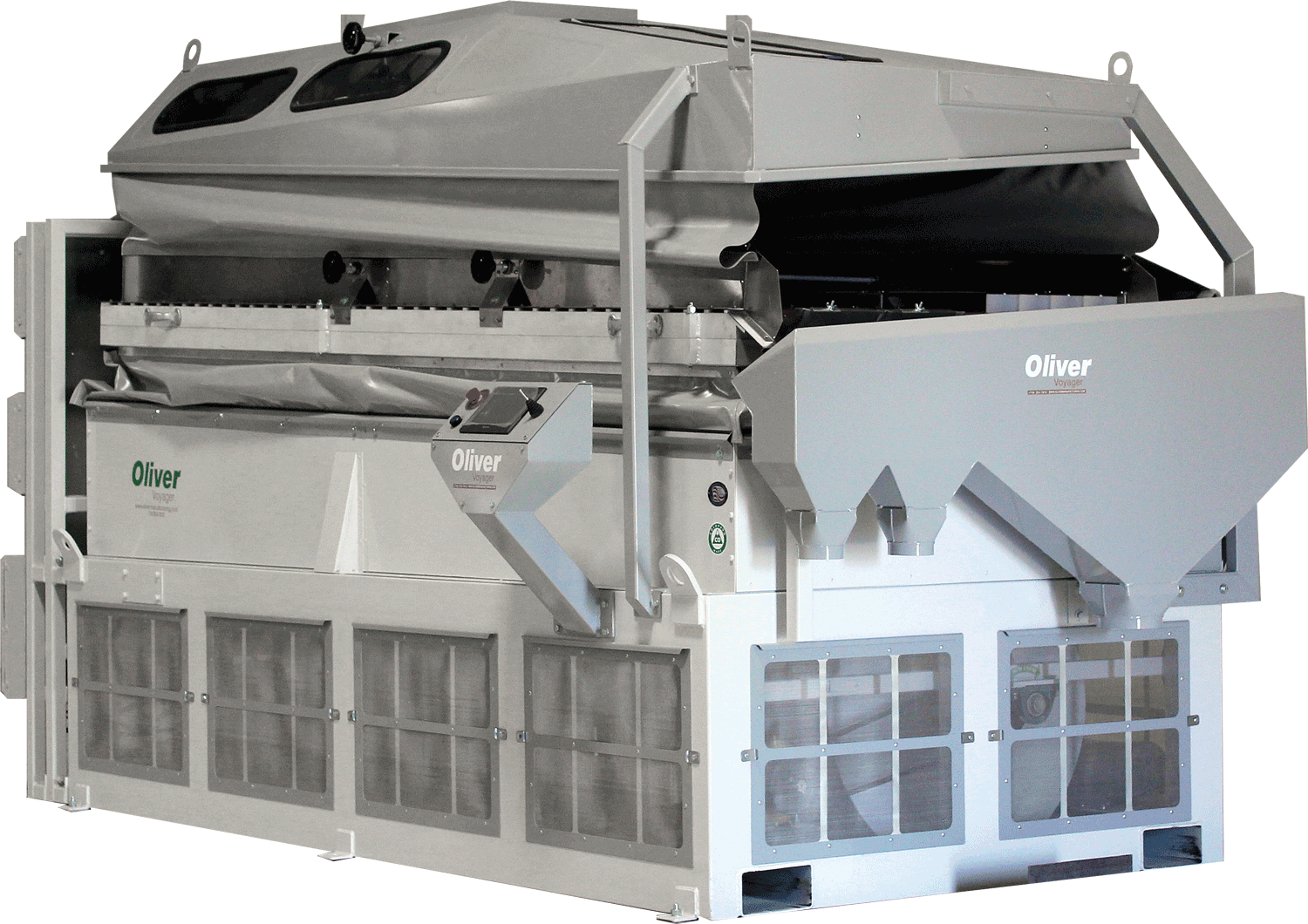

Reliable. Accurate. Efficient.

Built on our legendary rugged chassis and components, Voyager offers an unparalleled number of adjustment points and power automation to simplify the purification setup. Programmable Logic Circuitry with a pre-loaded menu of up to 20 separation “recipes” means faster and simpler changeover between different products, and optimal separations from even the most minimally-trained operator no matter what your density separation, size separation or contaminant removal needs.