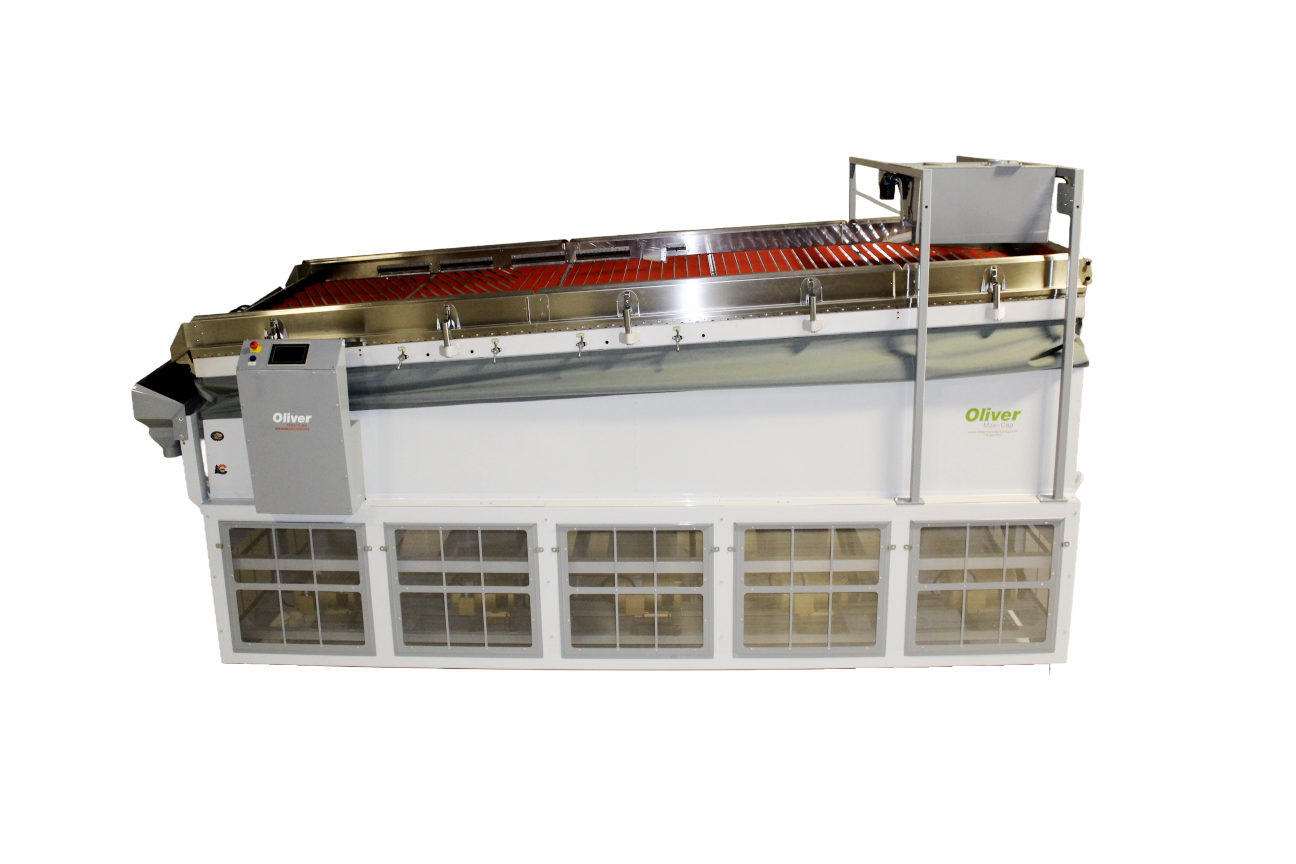

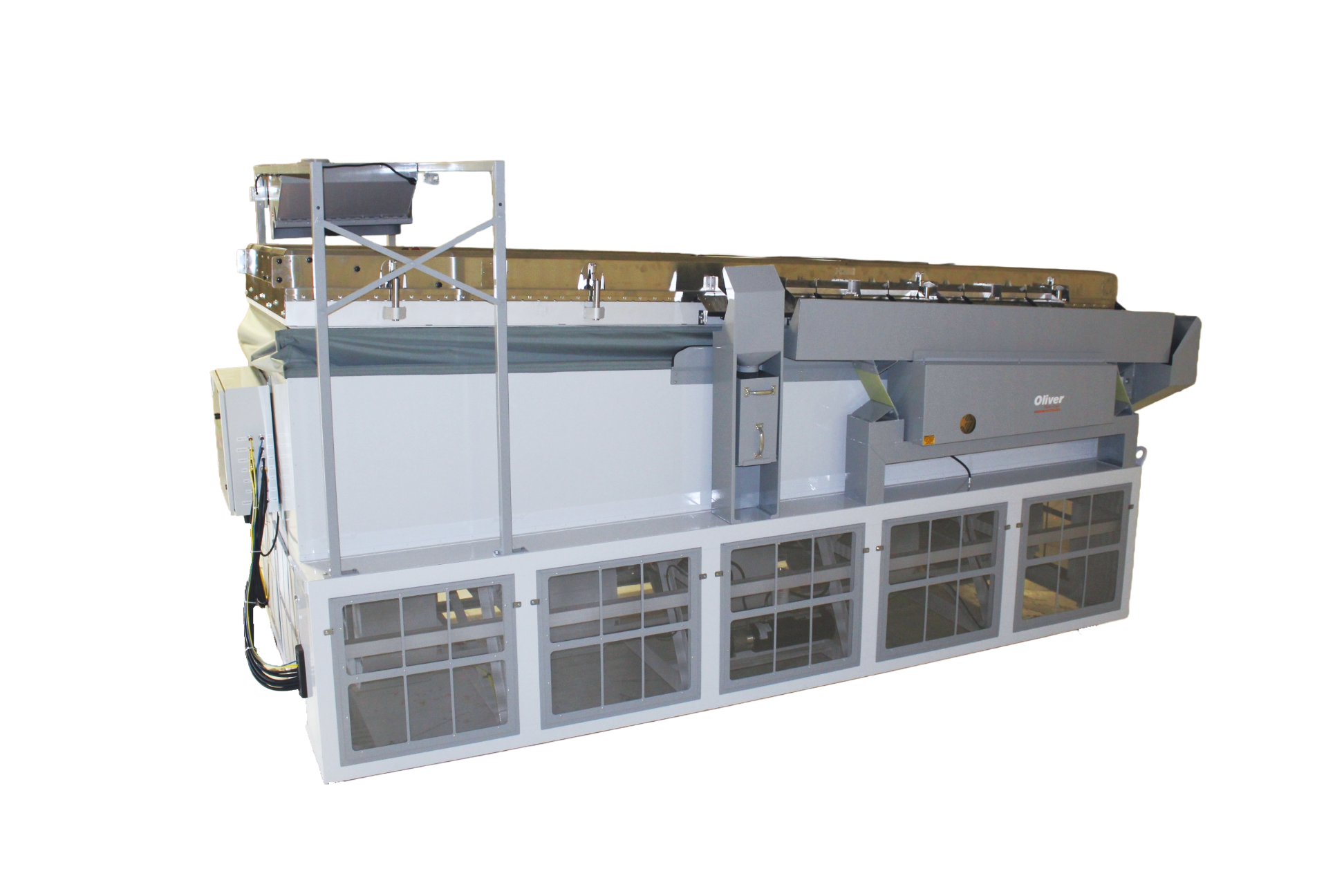

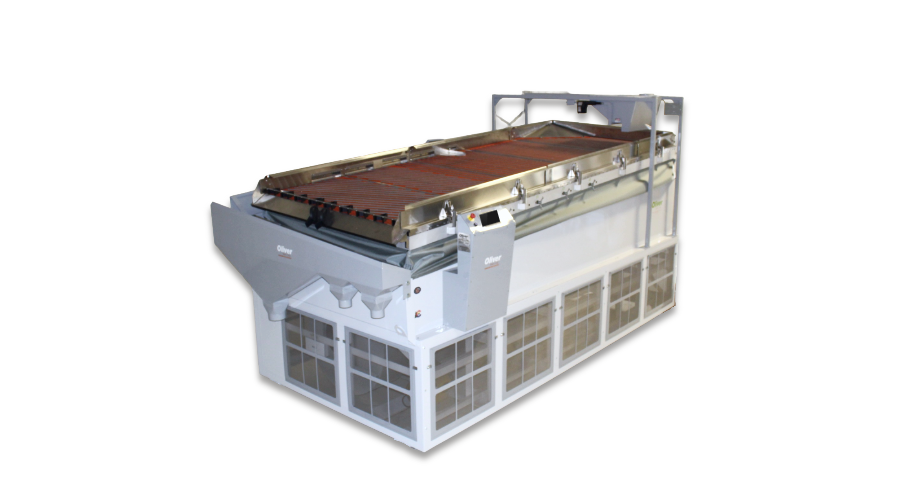

One of the most advanced automated high-capacity separators on the market, the Maxi Cap Platinum adds one-touch power electronic control and repeatable memory to a proven separator platform, capable of separating up to 40,000 lbs of material an hour. Instant power control of all parameters – fan speeds, table tilt, eccentric motion, and material feed rates – can be made through joystick and touchpad input or recalled from among up to 20 memorized setups.

Maxi Cap Platinum

Product Resources

Parts Lists

Brochures

Additional information

| Purpose | Separating |

|---|---|

| Industry | Food, Industrial Applications, Seed and Grain |

| Capacity | Large |

| Technology | Smart |

Product Features

| Machine Model |

3600 PL |

4800 PL |

|||

| Product |

Bulk |

lb/hr | CFM | Capacity | CFM |

|

Corn |

56 |

28,600 | 22,000 | 42,900 | 28,000 |

|

Cotton Seed |

43 |

21,000 |

22,000 |

31,500 |

28,000 |

| Lentils |

60 |

21,000 |

22,000 |

31,500 |

28,000 |

| Peas |

60 |

24,800 |

22,000 |

37,200 |

22,000 |

| Pinto Beans |

60 |

22,800 |

22,000 |

34,200 |

28,000 |

| Popcorn |

56 |

21,000 |

18,000 |

30,800 |

22,000 |

| Soybeans |

60 |

27,600 |

22,000 |

41,400 |

28,000 |

| Wheat |

60 |

22,800 |

18,000 |

34,200 |

28,000 |

- Built-in touchscreen, control platform (PLC) provides control of airflow, deck speed, eccentric speed, feed rate, and ability to save and load recipes

- Integrated E-STOP circuit

- Most precise adjustments on the market to fine-tune your separation

- Save and recall multiple recipes (such as automatic cleanout), through the PLC touchscreen interface

- A separate air system for operation is not required

- Dynamic controls are adjustable while the machine is in operation, including:

- Deck tilt

- Airflow

- Eccentric speed

- Product feed rate

- Nearly 100 years of experience in gravity table engineering and manufacturing

- UL and CUL-approved electrical cabinets

- Post-purchase training and machine service packages are available

- Spare parts are available upon order

- Rectangular deck design with custom overcover and undercover to allow for maximum product separation time

- Reduced machine setup and cleanout time

- Efficient air zone control from initial stratification through final discharge for optimal separation performance

- Counterbalanced for smooth operation, with low noise at operator level (88db)

- Integration with plant SCADA is available

- The modular deck makes for ease of maintenance and quick changeover from product to product and deck to deck

- Options include:

- Discharge hopper

- Partial or full dust hoods

- Vibratory feeder

- Deck configurations

- Recipe development

- Stainless steel contact points

- Control packages

Specifications

| Machine model |

3600 |

4800 |

| Height |

98” (249 cm) |

104” (264 cm) |

| Width |

111” (282 cm) |

123” (312 cm) |

| Length |

180” (457 cm) |

216” (549 cm) |

| Weight |

6,400 lbs (2,903 kg) |

8,200 lbs (3,719 kg) |

| Deck area |

57” x 142” (145 cm x 361 cm) |

69” x 178” (145 cm x 361 cm) |

| With deck hood | ||

| Height |

104” (264 cm) |

110” (278 cm) |

| Weight |

7,900 lbs (3,583 kg) |

10,000 lbs (4,536 kg) |

| Amp draw @480/3/60 |

70 amps |

80 amps |

| Amp draw @240/3/60 |

110 amps |

125 amps |

| Fan zones |

4 |

5 |

| Fan control |

VFDS |

VFDS |

| Warranty |

1 year |

1 year |